seven easy strategies to dramatically reduce the carbon footprint of buildings in cold climates in rural locations

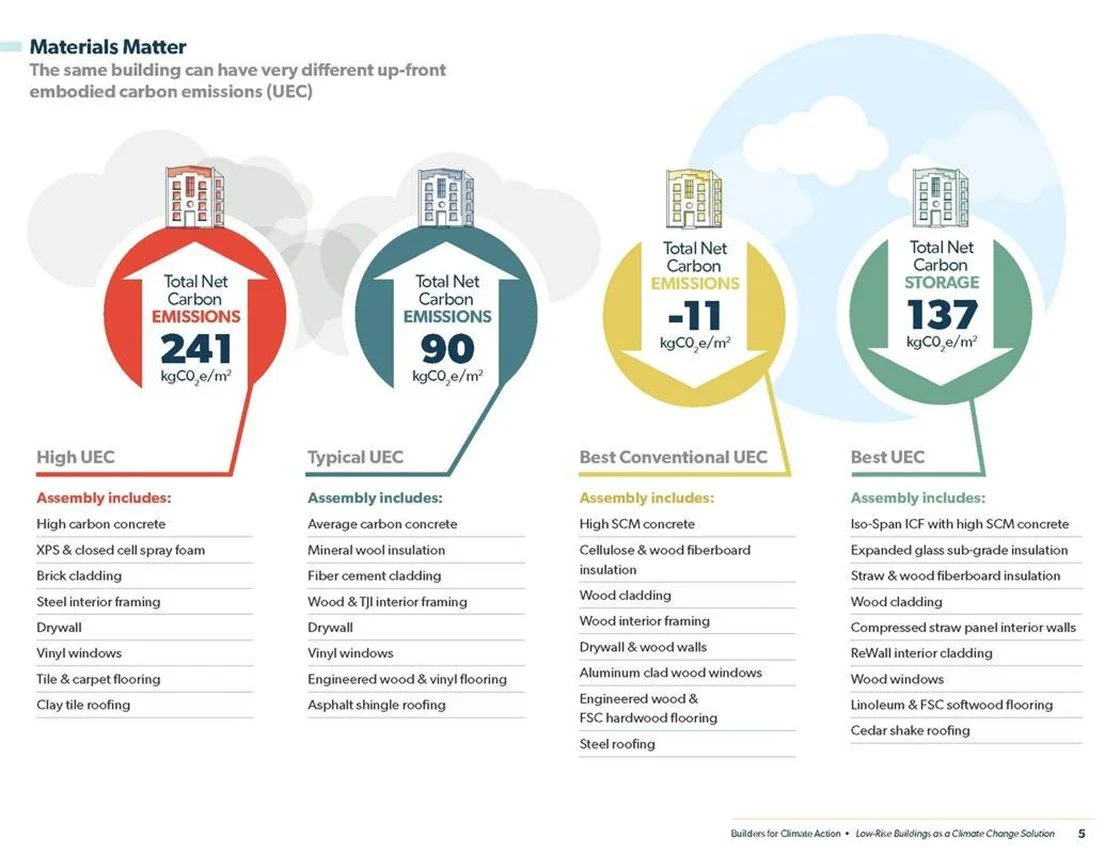

If the science about climate change is accurate, we have 3-7 years to dramatically reduce emissions in order to avoid the worst outcomes of climate change. AIA acknowledges and advocates that architects have a role to play in helping to reduce our global carbon footprint (https://blueprintforbetter.org/articles/design-resources-to-help-stop-climate-change/). We now know the embodied carbon in buildings is a huge contributor to overall emissions and that we must focus on reducing this as well as operational carbon, i.e. energy efficiency. Because buildings are such a significant contributor, they are also offer a significant opportunity for carbon storage (https://www.buildersforclimateaction.org/whitepaper1.html).

The point of this article is to help Idaho architects, engineers, and builders cut through the challenges of our region to realize the low-hanging fruit of implementing low and carbon negative materials in our projects.

In a fairly rural state, we face some challenges to implementing practices that help us reduce the embodied carbon footprint of buildings. The building industry evolves slowly, in general, and being a rural area, even more slowly. We are far away from material and product suppliers, professional peer and contractor learning may be slower than in more fast-paced markets, and our successful, leading high-cost markets happen to be fairly stable and un-motivated to evolve. The common sentiment is: why fix something if it is not broken, i.e. if it is making money?

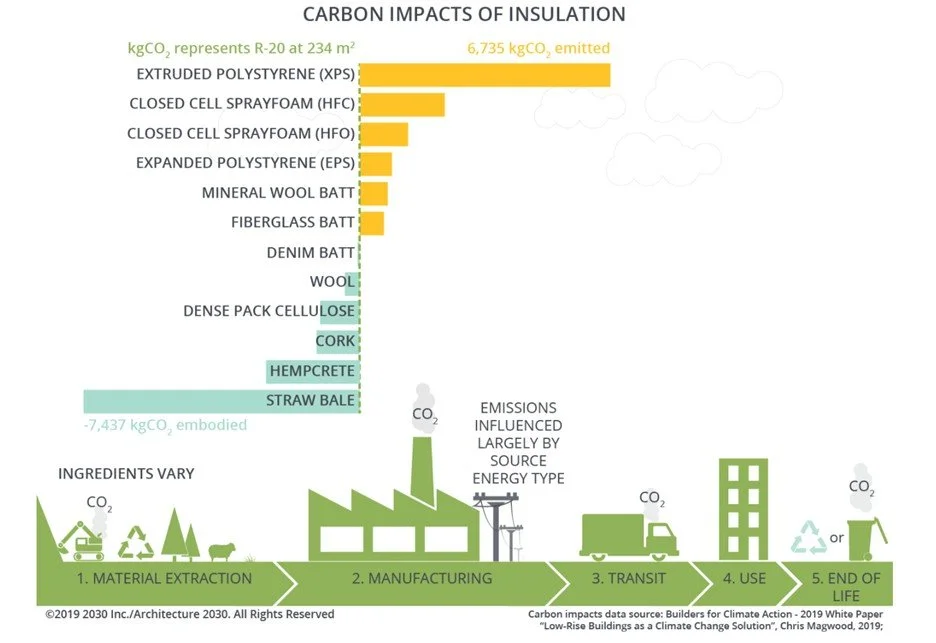

This list of seven strategies is simple to implement - these are tools you can begin to use today - and will make a dramatic difference. First, we have to understand the basics of an embodied carbon footprint. It helps to think of it in terms of currency: everything, all the “stuff” in our lives either put in or took out carbon the atmosphere. Too much carbon in the atmosphere is the problem which means too many things are putting it in rather than taking it out (storing or sequestering it). Some things that put carbon in actually “pay back” their input over time, however. Anything that puts in less than it takes out over its lifetime has a climate positive payback & if the payback period of the product is short, it is a good investment in our global health. Insulation is a primary example of this: it puts some carbon out as it is getting produced, but then it saves operational carbon over time. Some insulations do a better job at paying back than others: https://www.buildinggreen.com/news-article/avoiding-global-warming-impact-insulation.

Next, we should examine which components of the building are significant enough to have an impact on the overall embodied carbon: structure, insulation, and HVAC systems are the big ones. There’s a lot of “stuff” in the structure and insulation of a building, and so these are main aspects to target first. HVAC systems have much less “stuff” so it is not intuitive to think that these components have a great impact. Refrigerants in heat pumps and air-conditioning systems are the culprit & a simple refrigerant leak can wipe out any measures taken to reduce the operational or embodied carbon of a good building. We’ll focus on the assemblies, or the “stuff” in this article, but here is a good reference read about refrigerants: https://www.greenbuildingadvisor.com/article/reducing-refrigerant-leaks-from-heat-pumps.

1. Cheaper is better…say what?!? Not always, but Occam’s Razor holds true in many instances of construction as well as in physics (because building is physics!). Quite often the simplest, cheapest solution is the best for the planet.

There’s so much to unwind in this subject, but in general, less processed and especially plant or bio-based materials have low-carbon impacts and in the case of plant-based, there is potential for carbon-storage, depending upon the practices of the harvesting and processing, i.e. forestry or farming practices, lumber company, the mill, transportation, etc. A good rule of thumb is to use wood instead of steel or metal framing as much as possible, and use plant-based insulation whenever possible. If you can specify FSC or SFI wood products, then you will have a carbon storage effect. If not, at least the number will be low.

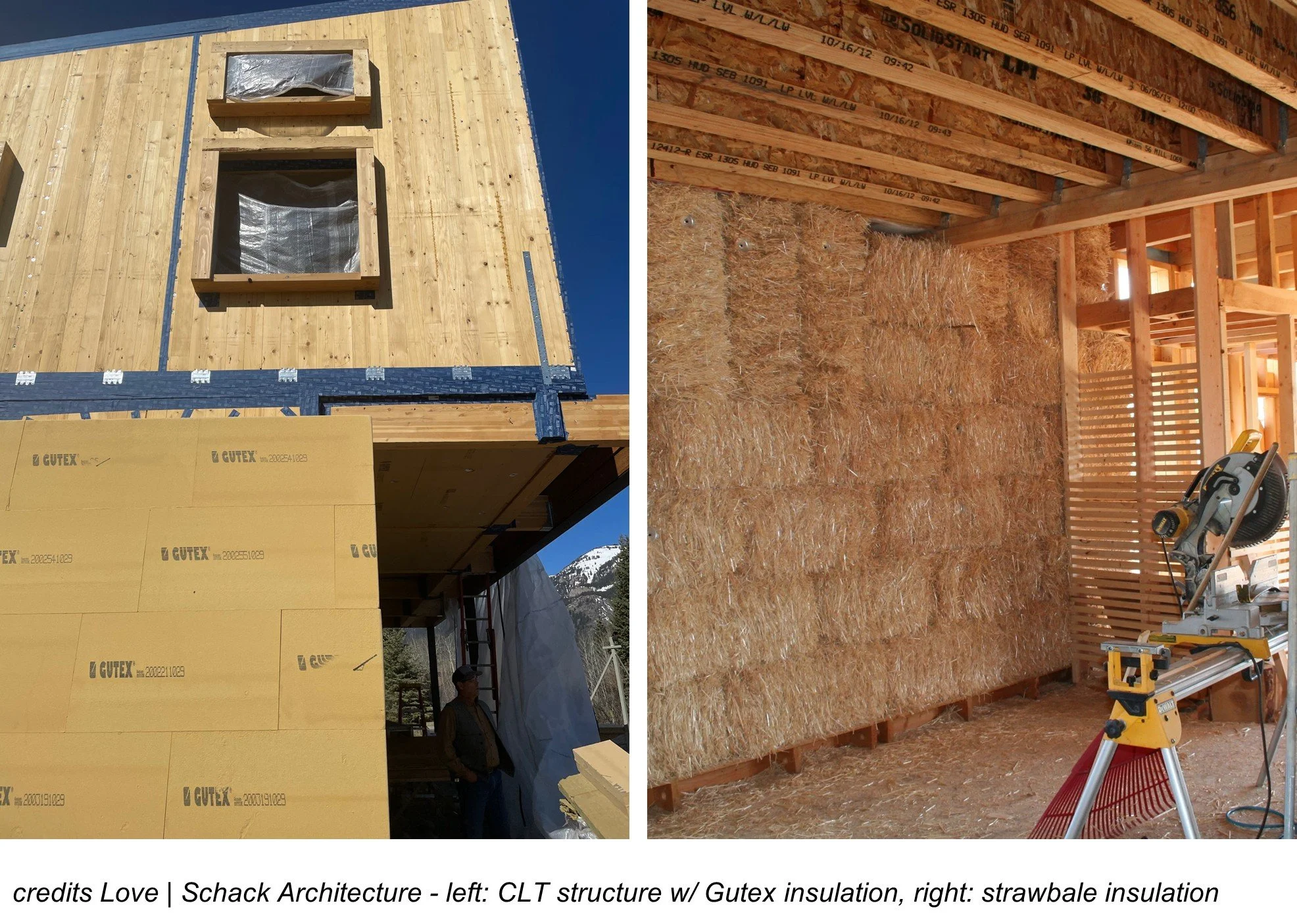

A great side-benefit of wood, although it is not as sleek or low-profile as steel, is that it has far less thermal conductance & therefore helps to reduce thermal bridging and condensation w/in assemblies which helps a building stand up longer. CLT (Cross-laminated-timber) is beautiful and regional and can replace steel or concrete in many instances. CLT is produced regionally by SmartLam: https://www.smartlam.com/.

If you cannot use cellulose, hempcrete or straw, then use fiberglass, hemp batts (not on the graph, but falls between denim and wool and will very soon be Idaho-produced! https://www.hempitecture.com/), or basically anything besides XPS and spray foam.

The second aspect of cheaper is better is that a code-built (yes, even an Idaho code-builtbuilding, i.e. R-values from 2009) can actually be better than a high-performance building. Anything with super high R-values that is relatively thin (XPS, spray foam) took a very large amount of energy to produce. We love Passive Houses, but when they are packed full of high energy foam insulation (spray foam or XPS), they probably have done more harm than good, i.e. their payback period may be longer than the functional life of the building or at anyrate is much longer than we have time to curb climate change. A Passive House insulated with cellulose, on the other hand, will do good by the climate over a relatively short period of time. The payback period is short.

2. So you’ve made a choice to use low-carbon materials - great! Now you have to figure out how to get that flat roof be air-tight and keep your roof sheathing from rotting, how to get a good R-value in the walls, and what to use below grade. It may not be possible to implement these materials in a building that is already fairly designed w/out making some big changes, but it might.

From the top down, here are some guidelines:

Roofs: again, cheaper is better: Whenever the design allows for a simple wood truss-roof w/ blown-in insulation and venting above the insulation, do this! And allow for a good high energy heel. Good design can work around aesthetic challenges. Embrace the energy heel and work with it! Every contractor knows & loves this system - challenges to implementation will be low.

When the design really calls for a low-slope, flat, or vaulted roof you have more limited options, but there are still options. The most conventional strategies are to “flash-and-batt” or add rigid insulation over the sheathing. Minimize the amount of rigid or foam insulation you use, but it must be adequate enough to prevent condensation (include link). As always, use mineral wool (Toprock) or EPS, or anything besides XPS. Maximize the amount of dense-packed insulation. You can get air-sealing with the flash and batt strategy, but only as long as the spray foam does not become brittle and crack, and only if it is installed properly (include link). In the high-performance building science community, spray foam is not considered a “durable air seal.” But, based on availability of innovative, educated, or like-minded contractors, this may be the option w/ the least harm.

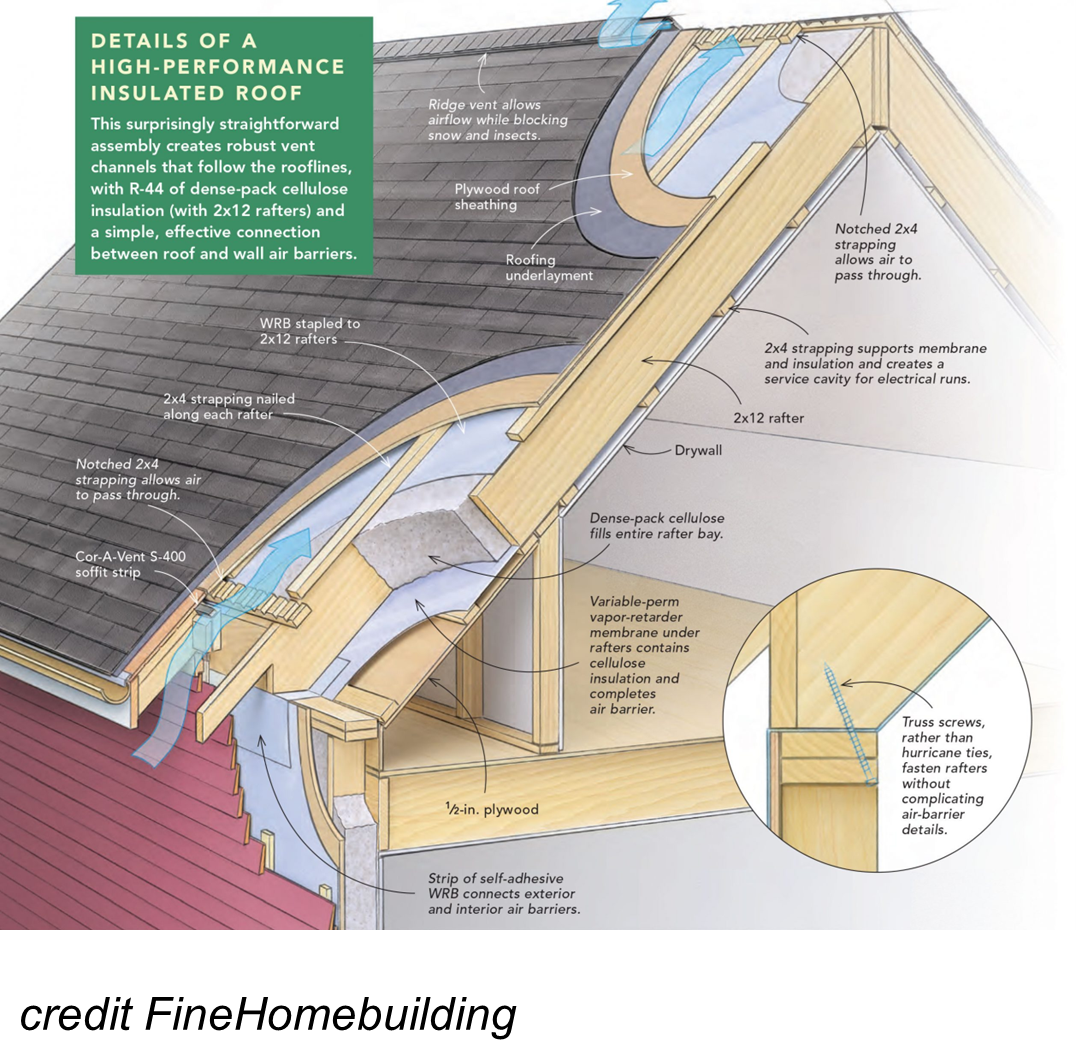

The next option, when adequate slope allows excellent venting, a structural rafter, truss, or joist roof that is dense-packed w/ a low carbon insulation can be covered w/ a cold roof such as this (https://www.finehomebuilding.com/2021/04/28/a-new-take-on-insulating-a-roof). In areas where labor is extremely expensive, and depending upon the pitch of the roof, contractors may argue that this is more expensive than spray foam. It is possibly true, but it is not necessarily true. It depends on the contractor, more than the system.

For a flat or low-slope roof, it is more imperative that the contractor be educated and willing (https://foursevenfive.com/blog/the-ten-golden-rules-for-foam-free-flat-roofs/). A high-R-value, dense-packed roof such as the one above can be left unvented if there is no chance of moisture entering the insulation cavity and if whatever moisture may sneak it’s way in can get out. This requires excellent air sealing with tapes and caulks at every penetration as well as a chase to eliminate most penetrations, i.e. an electrical chase framed below the roofframing. This assembly is risky and building scientists argue about how risky. Idaho has, in general, a very dry climate, so the risk is lower here.

In the two dense-packed options, the use “smart membranes” and excellent air sealing is very important. A smart membrane with smart installation, i.e. a plan for how to apply it at each junction, keeps moisture vapor out of the assembly but also allows it to escape to the interior. Not every contractor is aware of smart membranes, but some common options are (insert list), and most contractors in our market are familiar w/ CertainTeed products and will be more open to this version, Membrain, rather than unknown brand. Performance, installation, and permeability vary but this article discusses the most common: https://www.finehomebuilding.com/project-guides/insulation/smart-vapor-retarders-for-walls-and-roofs.

Walls: champion a thick wall! Thick walls are the best walls. Thick walls inherently feel better to humans than paper thin ones - they are more sheltering. And, at each window there is an opportunity for something interesting: angled window jambs allow light to reflect and fill a room more softly and deep sills create places to sit or place objects. With low-carbon or carbon storing insulations, we give up some R-value per inch, so we have to add inches back in.

There are a couple of options for where those inches can go, relative to the sheathing layer, similar to a roof.

• Exterior insulation provides better performance by reducing thermal bridges, and we get the benefit of keeping the sheathing warm, i.e. avoiding condensation. It creates some challenges w/ fastening siding, but this is a fairly conventional practice nowadays and most contractors have gotten over their fear that the fastening will fail. We know that the compression of the fasteners can provide enough friction to overcome the force of gravity. There are some performance aspects of different insulations to consider, i.e. how water/air/vapor interact with them that are important to learn because the WRB must be installed differently w/ say mineral wool boards than with wood fiberboard.

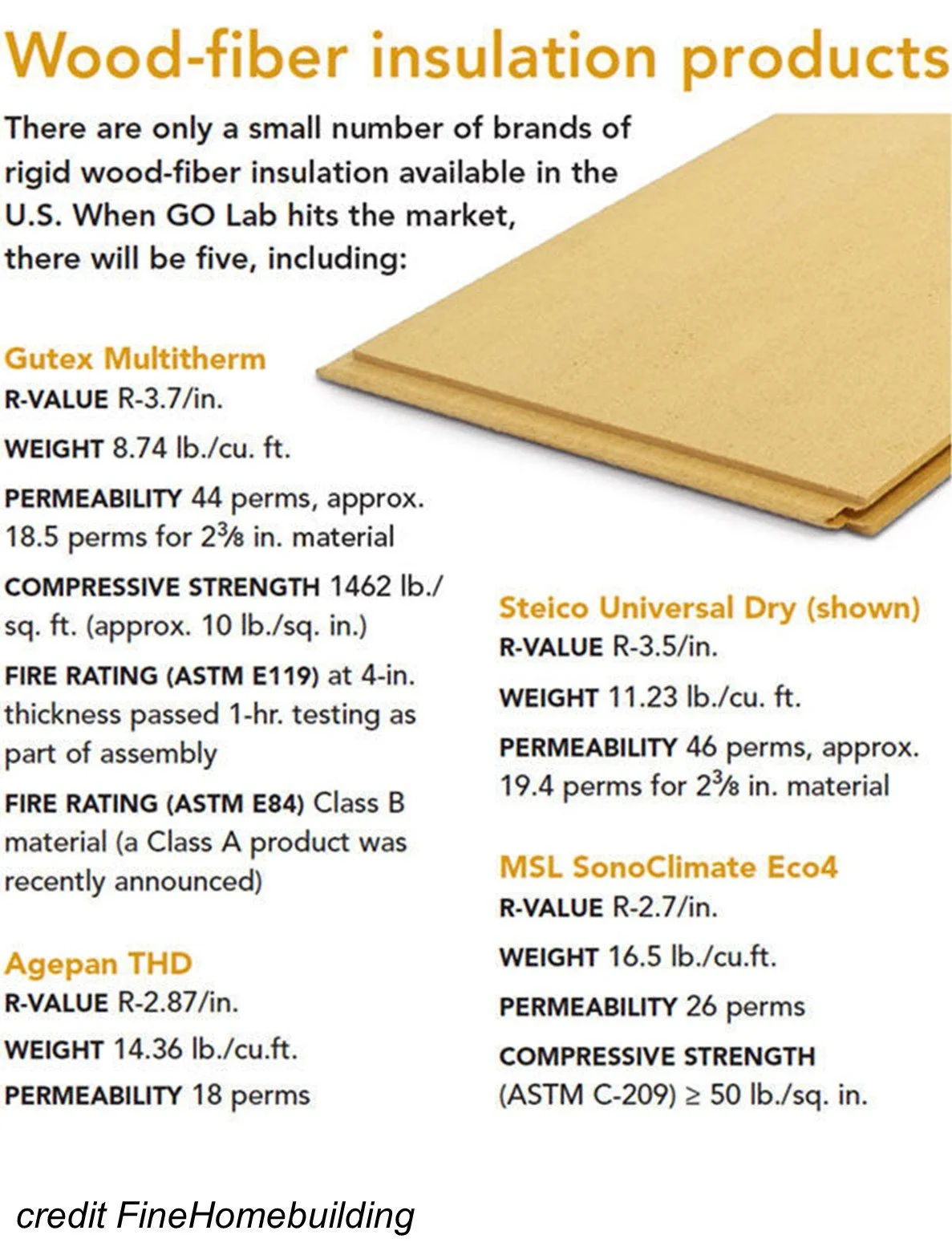

It is possible that rigid wood fiberboard could be the game-changer in reducing embodied carbon in buildings. Some of the products can actually act as the WRB, thereby also reducing labor costs, and some provide shear support - thereby eliminating the need for sheathing in some seismic zones https://www.finehomebuilding.com/project-guides/insulation/284-in-favor-of-wood-fiber-insulation! The only current producers are in Canada and Europe, but GoLab will come online in Maine in the near future : https://golab.us/for-immediate-release/#more-1247

• Interior insulation can be increased by increasing the width of framing either by using 2x8s instead of 2x6 structural walls or adding an extra wythe of minimal 2x3 or 2x4 framing. Often spray-foam loyal contractors will agree that the extra cost of 2x8 framing lumber will offset the cost of foam insulation, so they can’t argue that “thicker walls are more expensive.” The R-value of a 2x8 wall w/ cellulose or batts is still not quite as high as the R-value of a 2x6 wall w/ spray foam, but most contractors will advocate for flash and batt over filling the entire cavity w/ foam so even if they build a 2x8 wall but ultimately go w/ their preference of flash and batt, the harm of foam is still reduced. If they end up filling the 2x8 cavity, well, then, you did more harm, but you also will have learned a lesson (personal experience) - work w/ contractors you trust and clients who trust you.

A double-stud wall is a can of worms in terms of options for thickness and insulation options. It’s less conventional, more challenging to frame, but because of the options it can be the right choice if you have a client who is willing to push the sustainability envelope with an alternative insulation such as straw bales. https://www.greenbuildingadvisor.com/article/a-case-for-double-stud-walls

Panelization helps us to conventionalize and control the worms in the can. When we start talking panels with contractors and clients, people care less about what is inside the panel and more about how much time they can save in a short building season. This can be a great strategy for bringing everyone over to your side. There is risk w/ panelization and there is more upfront investment. The panel company must be reputable and the shipping should not overwhelm the savings. Some reputable American and Canadian panel companies include:

• Tectoniks: https://bensonwood.com/tektoniks/

• Collective Carpentry: https://collectivecarpentry.com/

• Ecocore: https://ecocor.us/enclosure-systems-2/

• New Frameworks Gryphon Panels: https://newframeworks.com/blog/2021/2/12/gryphon-panels-info-amp-impact

Modcell (https://www.modcell.com/) and Ecococon (https://ecococon.eu/) are excellent European panel companies looking for US projects so they can begin to manufacture in the states.

Foundations: are challenging. Water and biodegradable materials do not mix and this is the most vulnerable part of the building. It is hard to get around using a higher-energy insulation while also preventing mold and rot. You must first decide if the insulation should be interior or exterior and how much moisture it will be exposed to.

• Exterior: If it is porous & the ground is wet, then the insulation value will disappear.

• Interior: A conditioned crawl space can help to control the humidity, but insulation must be installed properly against the stem wall because of wicking.

EPS, mineral wool, and foam glass (not on the chart of insulations) are three relatively easy options for this part of a building. Mineral wool is porous, but more conventional and be both in and outside of a stem wall. EPS has higher carbon footprint, but can be under a slab (specify compressive strength) or on a wall, inside or out. Foamglass is not yet conventional but replaces gravel.

• https://www.glavel.com/foam-glass-gravel/

3. Work w/ contractors you trust and clients who trust you (the second part comes easily when you start w/ the first part). This can go either chicken or egg first, but if you are adamant that your clients will be better served by working with a contractor who is on your team, then you will all more easily achieve the clients’ goals. This works very well, most of the time. If you do not have a contractor you trust in your circle, then reach out to different certification programs to find out who in your region is educated and interested. The construction industry is not as savvy about embodied carbon as they are about energy efficiency, in general, but EMU (link) provides affordable contractor training for Passive House methods that is very well done. Though they do not focus on embodied energy, they educate w/ a variety of types of materials and methods so contractors are exposed to all the options.

4. Take the easy way out, reduce friction: we must circumvent the “spray-foam as a do-it-all in one strategy”. Embrace membranes, tapes, and caulks, and then support your contractor through the “how to” - reduce the friction they feel about learning a new system. Take time to think through sequencing of installation of framing and membrane components and get their input - a little planning goes a long way towards reducing labor on site. Once you do it will be second-nature, just like spray foam is currently for many. Also: avoid gable trusses! They are really challenging to air-seal w/ membranes and tapes.

5. Take responsibility: your client hired your company for many reasons and they do not need to know how all the sausage gets made. They probably don’t care about the sausage as much as you think they do, so just do what you do.

6. Forget about embodied carbon (when talking w/ contractors and especially clients): most people don’t get it yet. Someday this will be mainstream terminology but until then our job is far easier when we speak the same language as clients. Communicating about a healthy indoor environment is something that everyone will be on board with from the beginning and it just happens that many high carbon materials also contribute large loads of toxins to our environment and potentially indoor air. Healthy materials is a parallel route leading to the same destination (unless we’re talking about manufactured antimicrobials - that’s another story).

7. Just do less harm: if everyone would start building high performance straw and hemp commercial and institutional buildings and singing Kumbaya tomorrow, that would be amazing. In the meantime, use your intuition to evaluate what you can bite off now and do it without looking back. Use each failure to learn and improve.